200+ MIL-certified substances

» 50+ Metal Alloys

» 80+ Engineering Polymers

» 70+ Specialty Resins

200+ MIL-certified substances

» 50+ Metal Alloys

» 80+ Engineering Polymers

» 70+ Specialty Resins

SLA/SLM/SLS/MJF/FDM Solutions

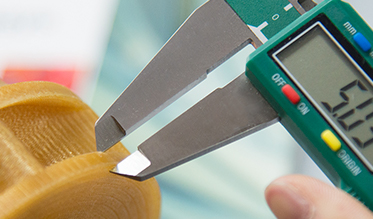

■ ±0.02mm dimensional accuracy

900+ industrial systems

100% compliance testing for shipment

■ AI topology optimization

■ Machine vision QC

□ 72hr express batches

■ Surface Engineering

■ Functional Integration

■ Structural Enhancement

■ Composite Process

[99.5% of the material is printable]

Metals: 70+ types; Resin: 50+types; Plastic: 30+ types; Ceramics: 20+ types; Other: 20+ types

Aluminum Alloy, Titanium Alloy, Stainless Steel, Mold Steel, Tungsten Alloy, Copper Alloy, Nickel-based Alloy, etc

White Resin, Black Resin, High Temperature Resistant Resin, Transparent Resin, High Toughness Resin, High-precision Resin, etc

PLA, ABS, PETG, Nylon (PA12/PA11), TPU, PEEK, PEKK, etc

Ceramics (Alumina, Zirconia),Sand (Silica Sand),Carbon Fiber Reinforced Composites,Biodegradable Materials (e.g., PCL)

3D Printing Parts Service

3D Printing Parts Service

3D Printing Metal Services

3D Printing Metal Services

3D Printing Nylon and Plastic Services

3D Printing Nylon and Plastic Services

3D printing of movable parts

3D printing of movable parts

3D printed golf ball head (titanium alloy)

3D printed golf ball head (titanium alloy)

3D printing of heat dissipation components (copper alloy)

3D printing of heat dissipation components (copper alloy)

3D printed metal Chinese dragon

3D printed metal Chinese dragon

3D printing bicycle parts

3D printing bicycle parts

3D printing of movable structural components

3D printing of movable structural components

Metal parts 3D printing services (aerospace)

Metal parts 3D printing services (aerospace)

3D printing of human faces

3D printing of human faces

3D printed Sichuan Opera figurines

3D printed Sichuan Opera figurines

3D printed titanium alloy bag

3D printed titanium alloy bag

3D printing of tiny metal parts

3D printing of tiny metal parts

3D printed metal earphones

3D printed metal earphones

Printing of drone structural components

Printing of drone structural components

3D printing of ultra precision structural components

3D printing of ultra precision structural components

3D printing of ultra precision small metal parts

3D printing of ultra precision small metal parts

Metal 3D printed badminton

Metal 3D printed badminton

3D printing aluminum alloy and other metal parts

3D printing aluminum alloy and other metal parts

3D printed metal aviation parts

3D printed metal aviation parts

Metal 3D printing of aerospace parts

Metal 3D printing of aerospace parts

Metal 3D printed circular structural components

Metal 3D printed circular structural components

Metal 3D printing for Guan Gong

Metal 3D printing for Guan Gong

Metal 3D printed motorcycle certification components

Metal 3D printed motorcycle certification components

Metal 3D printed electronic components

Metal 3D printed electronic components

Metal 3D printing of aerospace parts

Metal 3D printing of aerospace parts

Metal 3D Printing Medal

Metal 3D Printing Medal

Metal 3D printed bicycle components

Metal 3D printed bicycle components

Metal 3D printed heat dissipation parts

Metal 3D printed heat dissipation parts

Metal 3D printed dragon statue ornament

Metal 3D printed dragon statue ornament

Metal 3D printing circular porous parts

Metal 3D printing circular porous parts

Metal 3D printing super Bo titanium alloy scarf

Metal 3D printing super Bo titanium alloy scarf

Metal 3D printing of 12 zodiac animal images

Metal 3D printing of 12 zodiac animal images

Metal 3D printing precision components

Metal 3D printing precision components

Metal 3D printing of large spherical parts

Metal 3D printing of large spherical parts

Metal 3D printed golf club head

Metal 3D printed golf club head

Metal 3D Printing Jade Ruyi

Metal 3D Printing Jade Ruyi

Metal 3D printing cow

Metal 3D printing cow

Metal 3D printed butterfly

Metal 3D printed butterfly

3D printing of copper parts

3D printing of copper parts

3D printing of satellite components

3D printing of satellite components

3D printing of miniature parts

3D printing of miniature parts

3D printing spherical parts

3D printing spherical parts

3D printing of ultra-fine parts

3D printing of ultra-fine parts

3D printing of micro parts (rubber)

3D printing of micro parts (rubber)

3D printing resin service

3D printing resin service

11

11

3D printed colored bear

3D printed colored bear

3D printed shoes

3D printed shoes

3D Printing Plastic Services

3D Printing Plastic Services

3D printing of tiny parts

3D printing of tiny parts

3D printing car models

3D printing car models

3D printing on-demand service

3D printing on-demand service

3D printing of tiny sizes

3D printing of tiny sizes

3D printing of soft materials

3D printing of soft materials

3D printed shoe soles

3D printed shoe soles

3D printed jewelry

3D printed jewelry

3D printed dinosaur

3D printed dinosaur

3D printing medical models

3D printing medical models

3D Printing Plastic Character Model Service

3D Printing Plastic Character Model Service

3D printing services (nylon, resin, etc.)

3D printing services (nylon, resin, etc.)

11

11

3D printing of high rigidity parts

3D printing of high rigidity parts

3D printing of industrial parts

3D printing of industrial parts

3D printing ship

3D printing ship

3D printed dragon

3D printed dragon

3D printing cute animals

3D printing cute animals

3D printed portrait

3D printed portrait

Industrial 3D printing services

Industrial 3D printing services

3D printed heart

3D printed heart

3D printed turtle

3D printed turtle

3D printed lighting fixtures

3D printed lighting fixtures

3D printing of non-metallic parts

3D printing of non-metallic parts

3D printed audio system

3D printed audio system

3D printing surgical robot components

3D printing surgical robot components

3D printed chip components

3D printed chip components

3D printing 0.1mm small holes

3D printing 0.1mm small holes

3D printing of irregular gears

3D printing of irregular gears

3D printing of medical soft components

3D printing of medical soft components

3D printed crystal structure components

3D printed crystal structure components

3D printed brake discs

3D printed brake discs

Printing microfluidic chips

Printing microfluidic chips

3D printing of red wax components

3D printing of red wax components

11

11

"We are your secret weapon when your design challenges traditional manufacturing boundaries"

Founded in 2015, we have 3 industrial-grade production centers in China, disrupting the global cutting-edge manufacturing landscape with 2 micron printing accuracy, focusing on providing mission-critical 3D printing solutions for industries such as aerospace, medical and automotive. We have more than 85 certified engineers and more than 800 metal/special polymer printers (including EOS, Stratasys, HP, Platinum, LaMing and other brand equipment), and have delivered more than 10 million certified components to more than 50 countries.

We have helped 1,200+ global innovators become impossible to become reality:

ISO 8 cleanroom production space

minimum layer thickness capability

average rapid turnaround time

traceable material certificates

●Can detect internal defects of 10μm level

●"0 defects" quality control system to ensure the accuracy of the components is ±0.002mm

●Global production capacity intelligent scheduling system

●24/7 automated production monitoring

●Strict and complete customer confidentiality system

●Customer-only data cabin with destruction button

●15-person PhD team provides material modification services

●Can customize and develop special composite materials for complex extreme working conditions

●The cooling pipe mold of nuclear power plant damaged by the Japanese earthquake was rebuilt 72 hours a day

●Logistics services cover 120 countries and have an air emergency transportation network

●97% metal powder recovery rate

●100% use of green energy production

Challenge: Fabricate titanium alloy thruster brackets with extreme temperature resistance (-180°C to 300°C)

Solution: SLM + HIP post-processing

Achievements:

✔ 42% weight reduction

✔ Passed NASA STD-6012 certification

✔ Batch production cycle reduced to 72hr

Challenge: 4.7% fracture rate in orthopedic plates

Solution: Ti-6Al-4V ELI electron beam melting

Achievements:

✔ 2×10⁶ cycle fatigue life

✔ Fracture rate reduced to 0.3%

✔ AO Foundation recommended

Challenge: 18% corrosion rate in solar mounting systems

Solution: 316L stainless steel + micro-arc oxidation

Achievements:

✔ 5000hr salt spray resistance (ISO 9227)

✔ €1.2/m² installation cost saving

✔ UL 2703 certified

Challenge: 5G signal shielding in smartwatch antenna brackets

Solution: LCP material + RF-optimized lattice

Achievements:

✔ 4.2dB signal gain

✔ FCC Part 15 compliance

✔ 5x faster iteration

Challenge: Battery module endplates <800MPa strength

Solution: Topology-optimized maraging steel + stress relief

Achievements:

✔ 1450MPa tensile strength

✔ Passed GB/T 31485 nail penetration

✔ 2000pcs/day production capacity

Challenge: Made of titanium alloy thruster brackets that resist extreme temperatures (-180°C to 300°C)

Solution: SLM technology + thermal isostatic pressure post-treatment

Achievements:

✓ 42% weight loss

✓ Passed NASA STD-6012 test

✓ Mass production cycle shortened to 72hr

ISO14001

ISO45001

ISO9001

ISO 13485

AS9100D

IPMS

Upload STEP file to obtain:

☑ Manufacturingability analysis report

☑ Real-time price (including post-processing options)

☑ Delivery forecast

View online:

☑ Stress simulation heat map

☑ Suggestions for supporting structure optimization

☑ View live production broadcast

☑ Download quality inspection data

☑ Tracking global logistics status

Free first product:

Three coordinate detection report

CT scan packet

Test video

Raw material batch traced to the mine source

Production environment temperature and humidity record

Quality inspector bio fingerprint signature

We provide 3D printing parts services ranging from 1 to 100000 pieces,Please email us at xiaojiao2024@gmail.com.

Luotianshan

Luotianshan

Expert of space components manufacturing

Dusi

Dusi

Biomedical application expert

Huanghe

Huanghe

Auto parts manufacturing expert

Xiaoya

Xiaoya

Consumer Electronics Manufacturing Expert

Leiming

Leiming

Industrial Manufacturing Expert

Min. Order: 1 pieces

....